1970 Plymouth Superbird

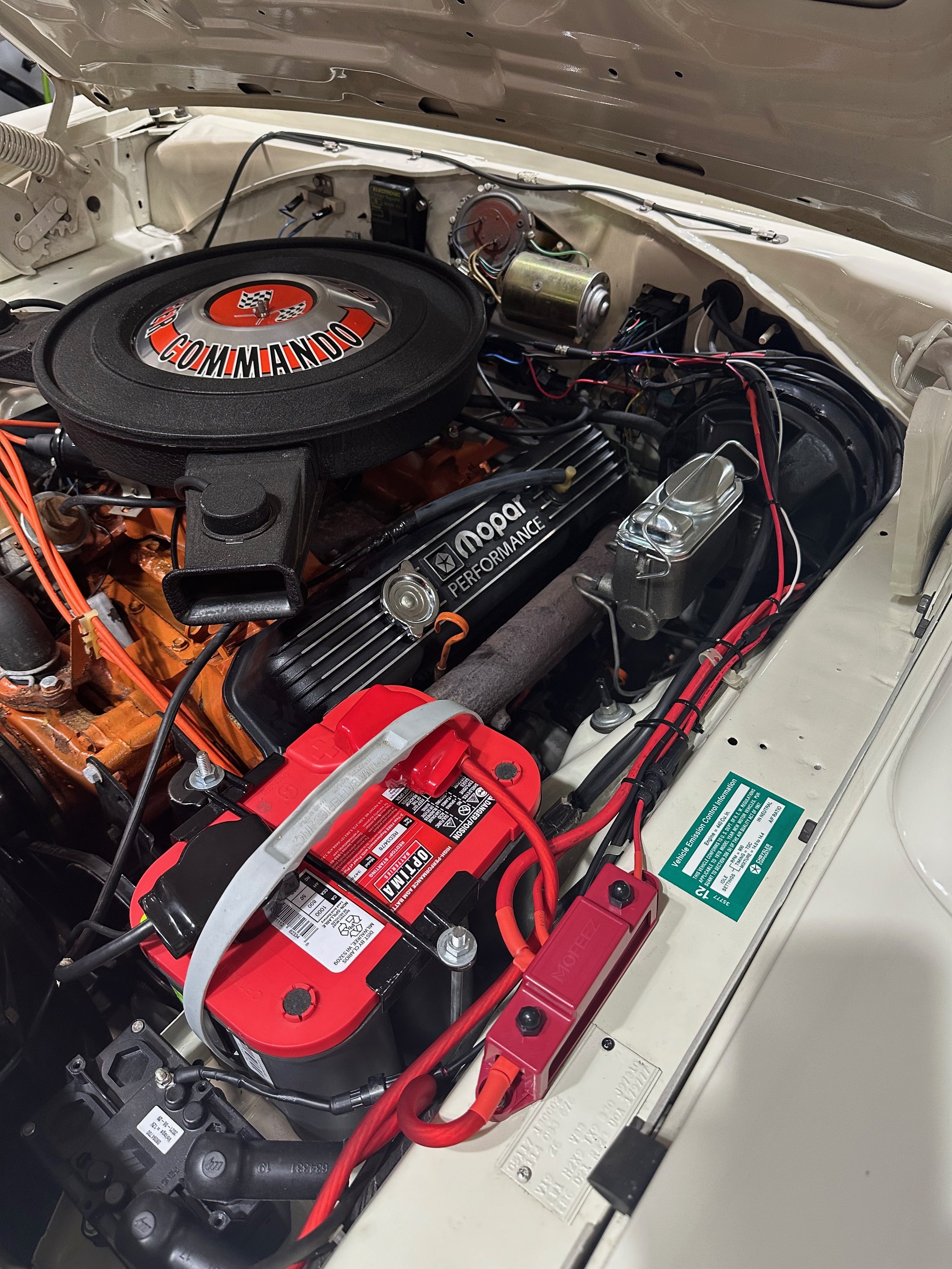

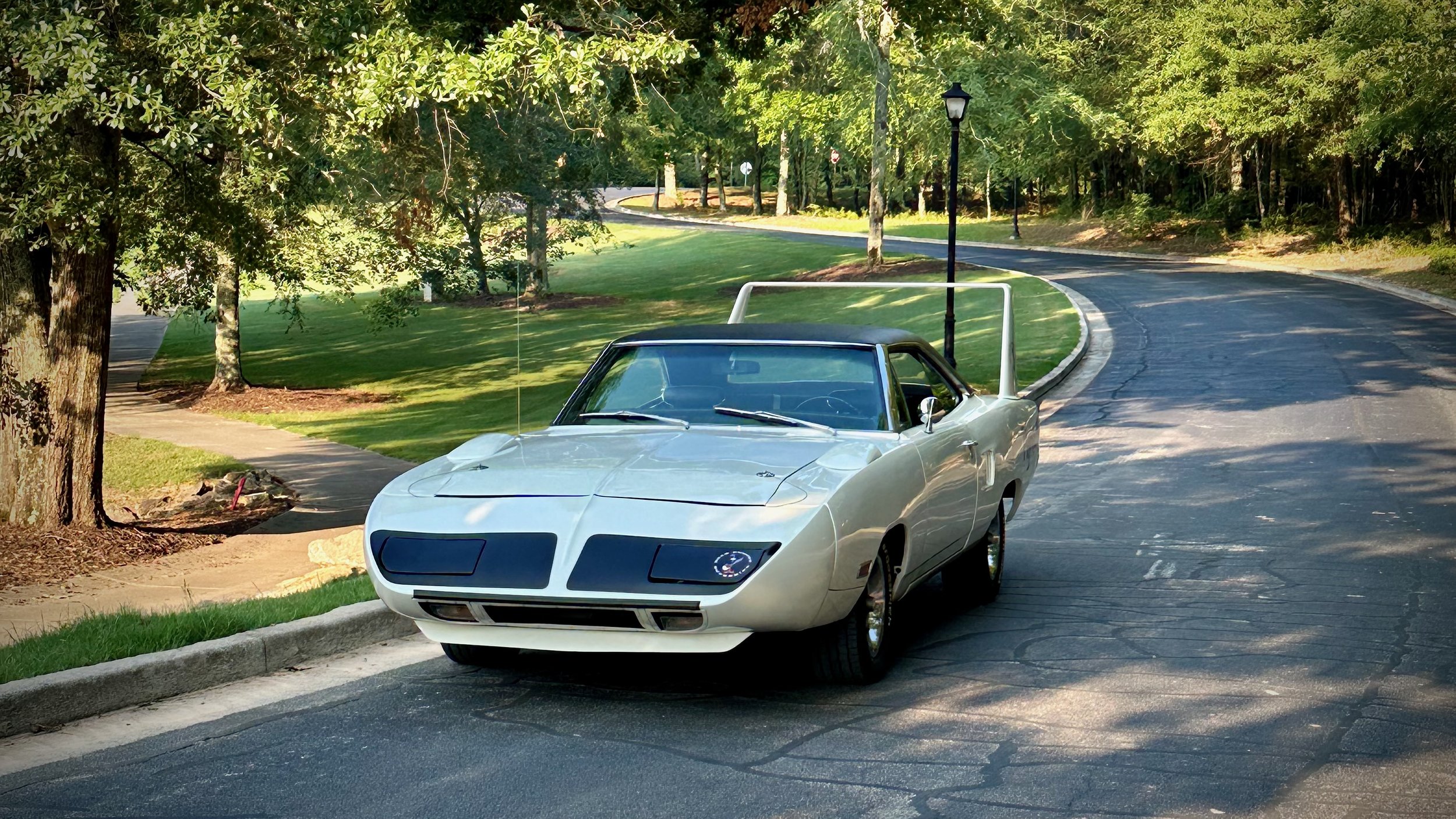

An ongoing project for MAD Garage is a very special, easily 1 of 1 vehicle, a 1970 Plymouth Superbird. This vehicle was not running since shortly after its restoration in the early 2000’s by Chip Foose and team. Due to personal reasons it collected dust and was not run. The owner came to MAD Garage with a proposal, let’s get this car back to a strong driver’s car. He purchased a Holley EFI system for it and put me to work sorting, cleaning, and modifying this 6500 original mile vehicle. Not only was it an incredibly low mile vehicle, both NASCAR driver’s that drove the Superbird in 1970 signed it, Richard Petty and Pete Hamilton.

The car was in a minor state of disrepair, but nothing that some fresh plugs and oil couldn’t sort out. I had to pull the fuel tank and replace with a new one, all new fuel lines, pump, return, etc. Additionally I added a positive battery disconnect that both aided me in installing the EFI system and saving the battery on a car that really doesn’t drive much at all (118 mi/yr!). Everything was a test of my abilities. Things that seem like they should be straightforward were either a custom project or delicate due to the location and not wanting to bang tools around on the car.

The troubleshooting was all worth it firing it up for the first time. Old cars are difficult to actually setup EFI in if they don’t have a constant 12v going to the ignition. This is one of the reasons I installed the battery switch and power bus. The Superbird was only getting at best 9v to the ignition, but we got it setup and programmed. The sensation of 500lb/ft of torque and a bench seat is something I recommend to everyone to experience at least once in their life if they can. The suspension is soft but manageable except when you hit a corner there is just nothing to hold onto and nothing holding onto you.

More recently the Superbird made another appearance at the shop for an equally momentous task of replacing the clutch and flywheel. Well after doing some inspections, I found that the transmission was not secured properly and the oil pan was not torqued properly and was leaking into the bell housing. This was causing uneven wear and excessive slippage on the factory setup. I got it setup with a 30% lighter flywheel and a stronger clutch package that really allows it to rev freely now.

Upon removing the transmission and knowing about the missing securing location at the transmission cross member, I saw that the input shaft was quite loose and could easily wobble back and forth. I dumped the fluid from the transmission and it was all glitter.. uh oh. That is absolutely not what I wanted to tackle but I worked myself into the game of attrition and bought the rebuild manual for that 4 speed. An A-833 transmission that had been used in basically every Chrysler product for 30 years. This does not, by any means, indicate that it is simple to do this or that the engineering was anything to utilize for the last 50 years but at least the information existed. Turns out the guy that wrote the book on the transmission is the one that’ll answer the phone when you need parts too. At least I had the parts figured out, although I had to order over the phone, with no tracking, no receipt, very old school. Oh and it took an equally painful amount of time waiting on parts for something that really is rare.

I had to save the transmission case as the VIN ends in 777 and with it being so low mile it would be silly to swap boxes in it. So I pressed on with my rebuild by the manual and the videos online. It was actually straight forward, but I found one part of the synchronizer selectors that had a huge chunk taken out of it from a blunt object. I was only at the end of the rebuild that I realized it was the detent ball for the gear selector that found its way out and into the metal blender of the transmission. The A-833 is a constant mesh transmission and the chunk was removed from the reverse gear on the synchronizer selector. There are actually two balls with a spring in between shoved into a short pipe on the side cover of the transmission. The bolts holding the gear selector had worked loose which allowed them to fall into the transmission slightly, which allowed the detent ball out. A simple fix and really; an anxiety inducing issue on that transmission. But, the excessive vibrations are what caused all the issues to begin with. It also meant the missing detent ball was what was causing the gear selector to feel odd. Technically you could shove it into 2 gears at once with the detent ball out of the picture.

Saying this transmission is large is an understatement. It’s pure Detroit iron, and that stuff is heavy. It also has a very long input shaft on the transmission. This makes installation almost impossible without pulling it the final distance with longer bolts on the engine and bell housing. I had seated it in there 3 times before I called a couple friends over to help me push it in there. Even the 3 of us only got it as far along as I could myself. Once I had some longer bolts though it was very easy, barely pulled on it, just needed to be lined up.

It was a surprisingly tight fit to get it around the one piece welded exhaust system and the body because the transmission was so large. Setting up the clutch was another task in itself as it’s an almost floating pipe with these plastic bushings inside on a bolt that had a ball on the end of it. This allows the shaft to move freely rotationally but not move in any other direction. It means that you have to hand thread a round piece between the transmission and inside the clutch Z lever (the pipe bit). To make it harder there was an additional Z bar bolted to the transmission that I couldn’t figure out what it did, bin it. Clutch action is now fantastic and really hooks up, a huge difference from when it first rolled in. It also shifts better, not great, the thing is still a 55 year old design. Driving it, I can tell it likes to be over 100mph. You can feel the aero taking effect above that speed and it’s only then that you really want to explore 4th gear.

It’s an experience I’m so pleased to be done with. Difficult projects teach us a lot along the way, this one was that the solution is not readily apparent pretty much the whole time while working on it, but to keep playing the game of attrition and you’ll succeed. I also learned to do this for me, not for anyone else or to prove anything to anyone else. The compensation is only part of the trade, but the project was my intention and my desire to troubleshoot based on all my background knowledge up to this point. I’m forever grateful for the experience to meet my hero Chip Foose through his work. No one is perfect, and I had the attitude that it was like visiting a National Park, leave it in better condition than you found it.